Soluble oils

Dosatron Solution

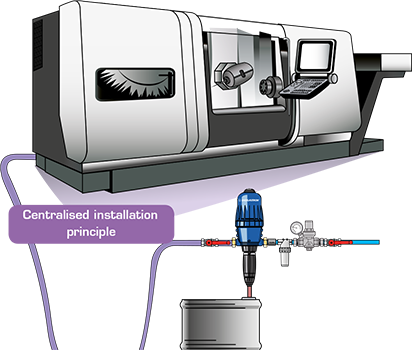

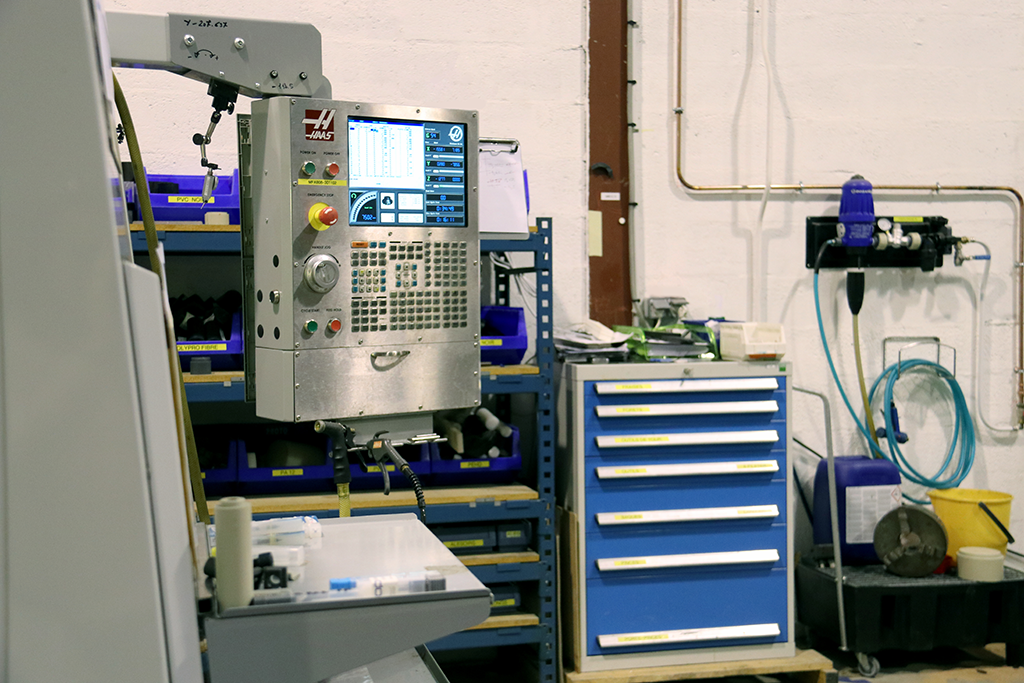

Incorporated in the water circuit, the Dosatron pump uses water pressure as its sole power source.

Driven in this way, the Dosatron can dose the various types of additive directly in the water feed tanks of one or more conventional or NC machines.

The precision and reliability of the Dosatron pump eliminate any risk of errors in the dosing and preparation of products such as emulsions and solutions.

The pump is not sensitive to the inherent variations (pressure, flow-rate, temperature, intake height and viscosity) of a fluid.

Constant emphasis on quality at all stages in the manufacture of the pump, both with regard to the materials used and the test and inspection procedures applied, ensures an optimum response to the requirements of metalworking machine tool users.

|

Cooling, lubrication & protection |

Dosatron advantages

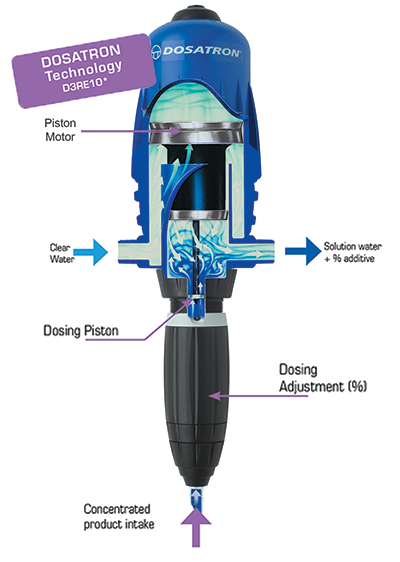

• Hydraulic, volumetric and non-electric

• Dosing proportional to water flow-rate

• Excellent dosing repeatability and final solution homogeneity

• Emulsion delivered directly downstream by water power

• Easy dosing adjustment at any time

• Self-priming up to 4M

Pump Selection

The appropriate Dosatron pump is selected firstly according to filling rate and secondly to dosing rate.

• Calculation of flow-rate requirement

Flow-rate is determined according to the required tank volume and filling time.

Example: 25-litre tank to be filled in one minute = flow-rate 1,500 l/h.

In this case you can select your pump in the 2.5 m3/h range.

If you wish to supply a number of tanks/machines simultaneously, or fill the tanks faster (if your available water flow-rate makes this possible), you should select a model in the 4.5 or 8 m3/h range.

• Choice of the dosing rate Particularity: proportional volumetric dosing

The Dosatron pump operates on the proportional volumetric dosing principle: the quantity of product injected is proportional to the quantity of water passing through the Dosatron pump.

Example: A 10% setting gives a solution of 10 parts concentrated product to 100 parts water In absolute % terms, this gives 9.09% (10/110).

*This Dosatron model is ideal for filling and adjusting, and answers a recurrent demand from professional users.

|

Recommendations for installation • Installation and utilisation in a drinking water circuit demands compliance with national standards and regulations in force. |

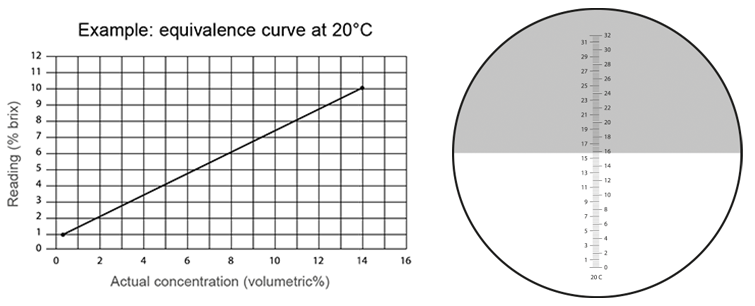

Do you check your emulsion with a refractometer ?

The initial % Brix readings given by your refractometer are not volumetric % values.

Consequently, you must:

• either calibrate your refractometer,

• or check the equivalence curve generally given by your oil or other viscous concentrate supplier in its technical data sheet.